Common Coupling Failures and How to Prevent Them

November 24, 2025

Why OEMs Trust Indian Coupling Manufacturers for Global Supply

December 10, 2025Key Takeaways:

- Primary Goal: The main function of a coupling is to transmit power while accommodating misalignment (angular, parallel, or axial) and damping vibration.

- High Torque vs. High Speed: For high torque/low speed, use Gear Couplings or Grid Couplings. For high speed/moderate torque, Jaw (Star) Couplings are the standard.

- Vibration Control: If your system suffers from shock loads (e.g., compressors), choose Tyre Couplings or Pin Bush Couplings for superior damping.

- Ease of Maintenance: RRL (Spacer) Couplings allow you to service pumps/motors without moving the equipment, saving hours of alignment time.

- Service Factor: Always apply a service factor (usually 1.5 to 2.0) based on your motor’s torque to handle startup spikes.

- Material Matters: Use Polyurethane or Hytrel spiders for harsh chemical environments, and Nitrile rubber for standard oil/heat resistance.

Introduction

Connecting a motor to a gearbox sounds simple, but it is one of the most critical decisions in mechanical power transmission. A coupling is not just a connector; it is the “fuse” of your mechanical system. The wrong choice can lead to shaft shearing, bearing failure, and expensive downtime. Conversely, the right coupling accommodates misalignment, dampens vibration, and ensures efficient torque transmission.

At Manglam Engineers, we understand that for plant managers and procurement heads, reliability is the only metric that matters. Whether you are operating a heavy-duty slurry pump or a precision conveyor, this guide will lead you through exactly how to select the perfect coupling for your application.

Why Is Motor and Gearbox Coupling Selection Very Important?

Selecting the right coupling is essentially an exercise in risk management. A motor and gearbox are rarely perfectly aligned. Thermal expansion, foundation settling, and manufacturing limits introduce misalignment.

If you use a rigid connection where a flexible one is needed, the forces generated by misalignment have nowhere to go but into your bearings and shafts. This leads to:

- Premature bearing failure.

- Seal leakage due to shaft deflection.

- Major shaft fatigue.

The goal of industrial couplings for motors and gearboxes is to transmit torque efficiently while compensating for these inevitable errors.

How Do I Determine the Right Coupling Size?

Calculating the correct coupling size requires more than just matching the shaft diameter. You must calculate the Design Torque.

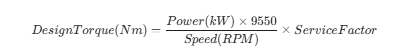

The Formula:

DesignTorque(Nm) = Power(kW)x 9550/ Speed (RPM)x ServiceFactor

Step-by-Step Selection Process:

- Identify Motor Power: Check the kW or HP rating.

- Identify Speed: Note the RPM of the driving shaft.

- Determine Service Factor:

- Uniform load (fans/blowers): 1.0 – 1.25

- Moderate shock (pumps/conveyors): 1.25 – 1.50

- Heavy shock (crushers/mills): 2.0+

- Check Bore Size: Ensure the coupling can be bored to fit both the motor and gearbox shafts.

Never select a coupling based solely on the maximum bore capacity. Always prioritize the torque rating.

What Are the Best Types of Couplings for Motors?

Different applications demand different mechanical properties. Below is a brief explanation of the specific products we manufacture at Manglam Engineers and where they fit best.

1. Jaw Coupling (Star Coupling): The Functional Standard

Jaw Coupling, often called Star Coupling, is the core of the general industry. It features two hubs with “jaws” and an elastomeric insert (spider) in between.

- Best For: Pumps, fans, compressors, and general conveyors.

- Why Choose It: It is fail-safe. If the spider fails, the jaws interlock, keeping the drive spinning (though noisily) until maintenance can occur.

- Key Component: The Rubber Spider or Normex Type Spider determines the torque capability and chemical resistance.

2. RRL & RRS Couplings (Spacer Type): The Maintenance Saver

In pump applications, “back-pull-out” maintenance is critical. You don’t want to unbolt the heavy motor just to change the seal.

- Best For: Centrifugal pumps and heavy ISO pumps.

- Why Choose It: The RRL Coupling features a spacer that can be removed, allowing you to disconnect the pump and motor without moving the equipment. This retains your precise alignment settings.

3. Pin Bush Type Coupling: The Shock Absorber

This coupling uses pins protected by Rubber Bushes to transmit torque through a flange. It is exceptionally good at handling shock loads.

- Best For: Elevators, winches, and drives with sudden start/stop cycles.

- Why Choose It: The rubber bushes compress to absorb significant shock, protecting the gearbox teeth from snapping during hard starts.

4. Tyre Coupling: The Misalignment Hero

When your alignment is tricky, or you expect significant foundation movement, the Tyre Coupling is unrivaled. It uses a flexible rubber tyre element.

- Best For: Crushers, mixers, and machinery on vibrating floors.

- Why Choose It: It can handle up to 4° of angular misalignment and significant parallel misalignment. Plus, replacing the tyre requires no tools or moving equipment.

5. Gear Coupling (GR Coupling): The Heavy Lifter

For massive torque in a small package, Gear Couplings are the answer. They use meshing gear teeth to transmit power.

- Best For: Steel mills, mining conveyors, and heavy crane drives.

- Why Choose It: Highest power density. If you need to move a mountain, you use gear coupling. Note: These require periodic lubrication.

Rigid vs. Flexible Coupling: Which Do You Need?

This is a common query in gearbox coupling selection guides.

- Rigid Couplings: Connect shafts solidly. They provide zero flexibility.

- Use only when: Shafts are perfectly aligned and will not move (e.g., vertical turbine shafts).

- Flexible Couplings: Accommodate misalignment.

- Use when: Practically anywhere else. 95% of motor-gearbox applications require flexible couplings like Jaw, Pin Bush, or Tyre types.

Primary Selection Factors: Beyond Torque

1. Misalignment Tolerance

- Angular: Shafts are at an angle. (Tyre Couplings are the best here.)

- Parallel: Shafts are parallel but offset. (RRL or Pin Bush handle this well.)

- Axial: Shafts move in and out (thermal expansion). (Jaw and Gear couplings allow floats.)

2. Vibration and Damping

If your gearbox drives a vibrating screen or a regenerative compressor, vibration can travel back up the shaft and destroy the motor bearings. You need a “soft” coupling.

- Solution: Use Tyre Couplings or Pin Bush Couplings with high-quality Rubber Bushes or Anti-Vibration Rubber Mounts at the base.

3. Environmental Conditions

Is the coupling exposed to heat, oil, or chemicals?

- Oil/Grease: Standard rubber may swell. Use Oil-Resistant Rubber O’Rings or Hytrel spiders.

- Heat: High temperatures require specialized polymers like Viton.

- Dust/Grit: SW Couplings or fully enclosed Gear couplings prevent abrasive wear.

Comparison Chart: Selecting the Right Coupling

|

Coupling Type |

Torque Capacity |

Misalignment Capability |

Shock Absorption |

Maintenance Level |

Typical Application |

|

Jaw (Star) |

Moderate |

Low |

Moderate |

Low (Replace Spider) |

Pumps, Fans, Blowers |

|

RRL (Spacer) |

Moderate |

Low |

Moderate |

Very Low (Drop-out spacer) |

Centrifugal Pumps (Back-pull-out) |

|

Tyre |

Moderate/High |

High |

Excellent |

Low (Replace Tyre) |

Crushers, Compressors |

|

Pin Bush |

High |

Moderate |

High |

Moderate |

Elevators, Heavy Conveyors |

|

Gear (GR) |

Very High |

Low |

Low |

High (Grease required) |

Steel Mills, Cranes |

Installation Best Practices for Longevity

Even the perfect coupling will fail if installed poorly.

- Laser Alignment: Always align shafts within 0.05mm if possible. The closer to perfect, the longer the rubber components last.

- Gap Setting: Ensure the “dbse” (Distance Between Shaft Ends) matches the catalog spec. If the gap is too tight, Jaw Coupling spiders will get crushed.

- Lubrication: If using Gear Couplings, establish a rigid greasing schedule.

- Inspect Rubber Parts: Check Rubber Spiders, T-Cushions, and Gaskets every 6 months. Cracking or powdering indicates it’s time to replace the insert.

Why Choose Manglam Engineers?

At Manglam Engineers, we don’t just sell parts; we provide power transmission solutions. From durable MT Couplings to precision Glass Ring Rubber components, our manufacturing process ensures tight standards and high-grade materials.

Whether you need a custom Rubber T-Cushion for an obsolete machine or a bulk order of RRL Couplings for a new plant setup, we deliver reliability.

- Wide Range: From Jaw to Gear, we manufacture it all.

- Customization: We can modify bore sizes and rubber compounds (Nitrile, Neoprene, PU).

- Durability: Our Anti-Vibration Rubber Mounts and coupling inserts are tested for Indian industrial conditions.

Need help calculating your service factor?

Our engineers provide a free sizing assessment to ensure optimal coupling performance.

Speak to an Engineer →Conclusion

Choosing the right coupling for motors and gearboxes is about balancing torque capacity with the ability to handle the unexpected – be it misalignment or shock loads. By selecting the correct type, whether it’s a flexible Tyre Coupling for damping or a rigid Gear Coupling for brute strength, you ensure the longevity of your entire drive train.

Don’t let coupling be the weakest link in your production line.

Ready to upgrade your power transmission? Explore our full range of Industrial Couplings & Rubber Mounts or Request a Quote directly to get the exact part you need, fast.

Frequently Asked Questions (FAQs)

For standard water pumps, a Jaw (Star) Coupling is cost-effective and sufficient. However, for larger industrial pumps where maintenance speed is key, an RRL (Spacer) Coupling is superior because it allows you to service the pump seals without moving the motor.

Choose a Tyre Coupling if you have significant misalignment (up to 4 degrees) or if the application involves heavy shock loading and vibration (like a rock crusher). Jaw couplings are better for aligned, steady loads.

In a standard Jaw coupling, no—you must move the motor back. However, if you use a Split-Spider or an RRL Spacer Coupling, you can replace the wear element without disturbing the motor or gearbox alignment.

It depends on the duty cycle. For 24/7 operations, inspect every 3–6 months. If you see rubber dust (powder) on the guard, the insert is worn out and needs immediate replacement to prevent metal-on-metal contact.

Yes. Unlike Jaw or Tyre couplings which are “install and forget” (until the rubber wears), Gear Couplings are metal-on-metal and require periodic greasing to prevent the teeth from wearing down and locking up.