Applications of Spider Star Jaw Couplings in Power Transmission

March 19, 2025

Understanding Different Types of Couplings: A Complete Guide

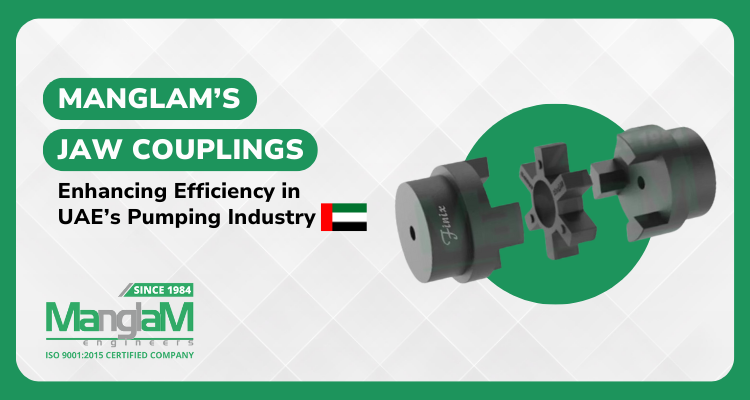

March 31, 2025Introduction: Why Jaw Couplings Matter in the UAE

In the fast-paced industrial landscape of the UAE, efficient power transmission is crucial for keeping operations running smoothly. Jaw couplings might not be the most glamorous components, but they're the important workers behind the scenes of the UAE's growing pumping industry. Manglam Engineers is a trusted brand, providing high-quality flexible jaw couplings. These couplings are transforming the performance of pumping systems in the UAE.

With the UAE's ambitious infrastructure projects and growing industrial sector, the demand for reliable and efficient coupling solutions has reached an all-time high. Whether it's in water management, oil and gas, or manufacturing, Manglam's jaw couplings are making a significant impact on operational efficiency and equipment longevity.

Understanding Jaw Couplings and Their Importance

What Are Jaw Couplings?

Jaw couplings are mechanical devices used to connect two shafts, allowing power transmission while accommodating minor misalignments. They consist of three main components:

- Two metal hubs with interlocking jaws or teeth

- An elastomeric "spider" that fits between the jaws

- Fastening components like screws or set pins

The elastomeric spider absorbs shocks and vibrations, making jaw couplings suitable for various industrial applications. Their simple design, ease of maintenance, and ability to dampen vibrations contribute to their widespread use.

Flexible jaw couplings play a crucial role in industrial pumping systems by

- Accommodating slight misalignments between connected equipment

- Transmitting power efficiently across drive systems

- Absorbing shock loads and dampening vibration

- Protecting equipment from damage due to startup torque or operational fluctuations

How Do Flexible Jaw Couplings Work?

Flexible jaw couplings in industrial pumping systems serve as important connectors between motors and pumps. The elastomeric spider between the metal hubs absorbs shock and vibration while allowing for slight misalignment between the connected shafts.

When the motor runs, the driving hub's jaws compress the spider material, transferring torque to the driven hub. This simple yet effective mechanism makes jaw couplings ideal for pump applications where reliability and performance are essential.

The elastomeric spider provides flexibility and vibration damping, making it ideal for the UAE’s demanding industrial conditions.

Key Benefits of Manglam's Jaw Couplings

1. Enhanced Durability for Industrial Applications

Manglam's jaw couplings are manufactured using high-quality elastomers that can withstand the harsh operating conditions common in the UAE's industrial environment. These materials resist:

- Extreme temperatures

- Chemical exposure

- Moisture and humidity

- Dust and particulate matter

This enhanced durability translates to longer service life and fewer replacements, making them a cost-effective solution for pumping operations.

2. Superior Vibration Damping for Smooth Operation

One of the standout features of Manglam's flexible jaw couplings is their exceptional vibration damping capability. This is particularly important in pumping applications where:

- Vibration can cause premature wear on equipment

- Noise levels need to be controlled

- Precision operations require stability

- Pump bearing life needs to be extended

The elastomeric spider absorbs vibrations, reducing stress on connected equipment and extending the operational life of the entire pumping system.

3. High Torque Transmission for Maximum Efficiency

Efficiency is a key concern in any industrial operation, and Manglam's jaw couplings deliver exceptional torque transmission efficiency. This means:

- More power reaches the pump from the motor

- Energy consumption is optimized

- Performance is maximized even under varying load conditions

4. Maintenance-Free Operation

Unlike some coupling types that require regular lubrication and maintenance, Manglam's jaw couplings offer virtually maintenance-free operation. This is because:

- The elastomeric spider requires no lubrication

- There are no moving parts that wear against each other

- The design is inherently simple and robust.

This maintenance-free characteristic saves time and money while ensuring consistent performance.

5. Cost-Effective Solution

When considering the total cost of ownership, Manglam's jaw couplings prove to be extremely cost-effective due to:

- Longer service life compared to conventional couplings

- Reduced maintenance requirements

- Protection of connected equipment from damage

- Energy efficiency through optimal power transmission

Application of Jaw Couplings in UAE's Pumping Industry

1. Industrial Pumping Systems

The UAE's manufacturing and production sectors rely heavily on industrial pumps for various processes. These applications need exceptional performance and reliability in challenging conditions. Manglam's jaw couplings provide the perfect solution for industrial pumping needs, offering better torque transmission and misalignment compensation. Their ability to withstand continuous operation while protecting expensive equipment makes them very valuable in industrial settings across the UAE. Manglam's jaw couplings are widely used in:

- Process manufacturing facilities

- Chemical processing plants

- Food and beverage production

- Pharmaceutical manufacturing

- Mining operations and material handling

These diverse industrial applications benefit from the consistent performance and reduced maintenance requirements that Manglam's jaw couplings provide.

2. Water Pumping Stations

The UAE's rapid development has created a huge demand for efficient water distribution networks. As cities expand and water consumption increases, the infrastructure must keep pace with growing needs. Water pumping stations form the backbone of this critical infrastructure, operating around the clock to maintain supply. The harsh desert environment adds another layer of challenge, requiring components that can withstand extreme conditions while maintaining peak performance. Manglam's jaw couplings play a key role in:

- Municipal water supply systems

- Groundwater extraction

- Irrigation networks

- Wastewater treatment facilities

Reliable couplings are essential for continuous operation in challenging environments.

3. Desalination Plants

The UAE's strategic approach to water security has made it a global leader in desalination technology. Converting seawater to freshwater is an energy-intensive process that places significant demands on pumping systems. Any downtime or inefficiency can have substantial economic and social impacts. The corrosive nature of saltwater presents additional challenges that require specially engineered components. With limited freshwater resources, the UAE depends significantly on desalination. These plants require:

- Highly reliable pumping systems

- Corrosion-resistant components

- Energy-efficient operations

Manglam's jaw couplings are specifically designed to meet these requirements, making them ideal for this critical application.

4. HVAC and Industrial Cooling Systems

In a region where summer temperatures regularly exceed 45°C, cooling systems aren't just a comfort but a necessity for human health and industrial operations. The UAE has invested heavily in advanced cooling infrastructure, from individual building systems to massive district cooling networks. These systems must operate at peak efficiency to manage energy costs while delivering consistent performance. The UAE's climate makes extensive cooling systems necessary, and Manglam's jaw couplings are important to:

- Chilled water pumps

- Cooling tower systems

- Industrial refrigeration

- District cooling networks

Their vibration-damping properties are particularly valuable in these applications where noise reduction is often a priority.

5. Oil & Gas Pumping Operations

As the foundation of the UAE's economic prosperity, the oil and gas sector demands the highest standards of equipment reliability and performance. From extraction to processing and distribution, pumping systems must operate flawlessly in extreme conditions. Equipment failure can result in significant production losses and potential environmental concerns. The advanced nature of modern petroleum operations requires components that can integrate seamlessly with advanced monitoring and control systems. The backbone of the UAE's economy, the oil and gas sector, uses Manglam's jaw couplings in:

- Crude oil transfer pumps

- Refinery processes

- Pipeline booster stations

- Offshore platform operations

The reliability and durability of these couplings make them suitable for the demanding conditions of the petroleum industry.

Why Choose Manglam's Jaw Couplings?

When it comes to industrial efficiency, choosing the right coupling makes all the difference. Manglam's jaw couplings are designed to enhance performance, minimize downtime, and ensure long-term reliability across various applications. With a commitment to innovation and quality, we provide solutions designed to meet the demanding needs of the UAE’s industrial sector.

1. Unmatched Engineering Excellence

Manglam Engineers sets the benchmark for quality with precision- designed jaw couplings that meet the highest industry standards. Our advanced manufacturing processes ensure superior performance, durability, and reliability across all industrial applications.

2. Customized Solutions for Every Industry

Unlike off-the-shelf solutions, Manglam Engineers provides customized coupling options designed to your specific operational needs. Whether it’s high torque requirements, extreme environmental conditions, or unique application challenges, we have the perfect solution.

3. Proven Performance & Client Satisfaction

Our jaw couplings have been extensively tested in real-world industrial environments, delivering consistent performance and longevity. Industry leaders across the UAE trust Manglam for their critical pumping systems.

4. Reliable Supply Chain & Quick Delivery

We understand the importance of minimizing downtime. With strategically located distribution centers and a well-stocked inventory, we ensure prompt delivery to keep your operations running smoothly. Our just-in-time delivery system guarantees you get the right couplings exactly when you need them.

5. Exceptional Support & Expert Guidance

Manglam Engineers goes beyond just supplying couplings – we provide expert support, ensuring you select the right product for maximum efficiency. Our dedicated support team is always ready to help with installation guidance, troubleshooting, and maintenance recommendations.

Need an upgrade or replacement? Trust Manglam Engineers for the best jaw coupling solutions in the UAE.

Get in Touch Today to Optimize Your Pumping System With the Best Jaw Couplings in the UAE.

How to Select the Right Jaw Coupling for Your Pump

Selecting the ideal jaw coupling ensures efficient power transmission and extends equipment lifespan. By evaluating key factors such as torque, speed, misalignment, and environmental conditions, you can choose a coupling that optimizes performance and reliability.

Key Selection Criteria

Choosing the right jaw coupling involves considering several factors:

1. Torque Requirements: Determine the normal operating torque and peak torque of your application.

2. Speed: Consider the rotational speed of your pump and motor.

3. Misalignment: Assess the potential for angular, parallel, or axial misalignment.

4. Environmental Conditions: Factor in temperature, chemical exposure, and presence of moisture.

5. Space Constraints: Measure the available space for the coupling installation.

Step-by-Step Selection Guide

1. Calculate Service Factor: Multiply your nominal torque by the appropriate service factor based on your application.

2. Determine Spider Material: Select the spider material based on your environmental conditions and damping requirements.

- Urethane: For general-purpose applications

- Hytrel: For high-temperature environments

- Nitrile: For oil-resistant applications

- Bronze: For high-temperature applications where elastomers aren't suitable

3. Choose the Coupling Size: Select a coupling size that exceeds your calculated torque requirements.

4. Verify Speed Rating: Ensure the selected coupling can handle your application's RPM.

5. Check Misalignment Capacity: Confirm that the coupling can accommodate the expected misalignment in your system.

Maintenance Tips for Optimal Performance

To get the most out of your Manglam jaw couplings:

- Regular Inspection: Check for wear on the spider at least twice a year

- Proper Alignment: Ensure shafts remain properly aligned during operation

- Timely Replacement: Replace the spider element at the first signs of wear

- Correct Installation: Follow manufacturer guidelines for installation torque

- Environmental Protection: Shield couplings from extreme environmental conditions when possible

Conclusion: The Best Jaw Couplings for UAE’s Pumping Needs

In the competitive industrial landscape of the UAE, every component matters when it comes to operational efficiency and reliability. Manglam's jaw couplings have proven to be a game-changer in the pumping industry, offering superior performance, exceptional durability, and cost-effective operation.

Whether you're managing water infrastructure, operating a desalination plant, or running industrial processes, Manglam's flexible jaw couplings provide the reliable power transmission solution you need. With their maintenance-free operation and excellent vibration damping properties, these couplings not only enhance efficiency but also extend the life of your valuable equipment.

Don't compromise on quality when it comes to your pumping systems. Choose Manglam Engineers for your jaw coupling needs and experience the difference that engineering excellence can make.

Ready to Enhance Your Pumping Efficiency?

Contact Manglam Engineers today for a free consultation on how our jaw couplings can improve your operations. Our team of experts is ready to help you select the perfect coupling solution for your specific requirements.

Call us at +91 78744 79699 or visit our website at www.manglamengineers.com to learn more.