Manglam Engineers has established itself as a leading manufacturer of jaw and star couplings in India since 1983 with a brand name finix. We utilize the most advanced technology and precision engineering to manufacture our couplings, ensuring they meet the exact requirements of our customers.

Our experience in the field has given us a deep understanding of the critical role couplings play in transmitting torque and accommodating misalignment within industrial machinery. To address these challenges, our skilled team of engineers has developed a comprehensive range of jaw couplings, available in sizes MS-070 to MS-350.

For our star couplings, we use nitrile rubber due to its exceptional resistance properties. This ensures optimal performance and longevity in demanding industrial applications.

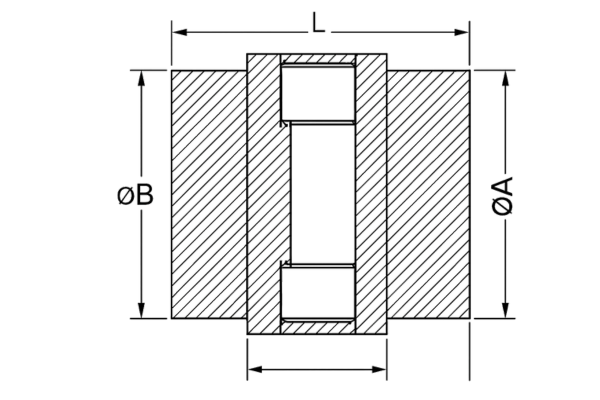

Jaw Coupling Drawing

Working Principle of Jaw/Star Coupling

| Jaw/Star Coupling Dimensions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Coupling Size | Torque NM | Kw at 100 RPM | Min. Bore | Max. Bore | ØA | ØB | L | Weight Approx | MOC |

| M 50 | 2.5 | 0.03 | 6 | 16 | 28 | 28 | 46 | 0.4 | CI/AL |

| M 70 | 4.9 | 0.05 | 9 | 20 | 35 | 35 | 51 | 0.5 | CI/AL |

| M 75 | 9.8 | 0.1 | 9 | 20 | 44.5 | 39 | 55 | 0.5 | CI/AL |

| M 95 | 21.1 | 0.22 | 10 | 24 | 54 | 49 | 63 | 0.8 | CI/AL |

| M 99 | 35.1 | 0.37 | 10 | 28 | 65 | 57 | 72 | 1.5 | CI/AL |

| M 100 | 46.4 | 0.49 | 10 | 28 | 65 | 57 | 88 | 1.8 | CI/AL |

| M 110 | 89 | 0.93 | 15 | 38 | 85 | 76 | 108 | 3.2 | CI/AL |

| M 150 | 141 | 1.49 | 15 | 42 | 96 | 80 | 115 | 4.5 | CI |

| M 190 | 190 | 2.01 | 20 | 50 | 115 | 102 | 133 | 6.5 | CI |

| M 225 | 265 | 2.75 | 20 | 55 | 127 | 111 | 153 | 9.1 | CI |

| M 226 | 324 | 3.45 | 25 | 65 | 137 | 119 | 178 | 12 | CI |

| M 276 | 532 | 5.6 | 25 | 70 | 157 | 127 | 200 | 18 | CI |

| M 280 | 782 | 8.2 | 30 | 80 | 192 | 140 | 200 | 24 | CI |

| M 295 | 1279 | 13.4 | 40 | 95 | 237 | 162 | 238 | 44 | CI |

| M 2955 | 2132 | 22.4 | 50 | 105 | 237 | 180 | 264 | 51 | CI |

| M 300 | 3047 | 31.9 | 50 | 105 | 254 | 180 | 283 | 58 | CI |

Jaw/Star Coupling Features

- Compact design

- Robust construction

- Precise dimensions

- Avialable in Cast Iron & Graded Aluminium

- Reliable performance

- Failure protection

- Excellent physical properties

- Easy installation

- Suitable for a variety of applications

Aluminium – Jaw Coupling/Star Coupling

Solving Power Transmission Challenges in the Industry

Why Our Product?

Application of Jaw/Star Coupling

Product Video

- Range: 50 mm to 160 mm

Leading Exporter of Transmission Couplings & Industrial Rubber Parts

From our advanced manufacturing hub to your factory floor, Manglam Engineers delivers precision and quality. As a globally recognized manufacturer and exporter, we specialize in Transmission Couplings and a wide range of Industrial Rubber Parts. We empower key sectors such as Industrial Pumps Manufacturer, Automotive, Agriculture, Chemical, Water Solutions, Mining, and General Manufacturing, exporting our precision components to Germany, United States, United Kingdom, China, UAE, Indonesia, and Sri Lanka.

Our success is driven by a commitment to innovation, quality, and our customers. We don't just sell parts; we build lasting partnerships. Experience the Manglam Engineers difference and let us be a part of your global success story.

Other Products

Best Transmission Coupling & Rubber Parts Manufacturer & Exporter

We are among India’s leading manufacturers of transmission couplings and rubber parts, delivering durable, precision-engineered solutions for reliable performance. From standard to custom components, our focus is on quality, efficiency, and reducing downtime - making us a trusted partner for manufacturing industries nationwide.

Experience superior performance with our advanced jaw/star couplings!

Fill in this Form for Inquiry